Cheng Hui: China Mobile Digital intelligence supply chain: from industry to industry

The airport in Fuzhou is a little far from the city. Every time the distance of bullet train is within 6-9 hours (similar to Guangzhou or Beijing), I will struggle with whether the transportation is by plane or bullet train. Sometimes, the calculation, the time to and from the airport, plus the waiting time, plus the high probability of delay and other factors, will choose bullet train. After taking the bullet train, I will check the state of the plane, and then have a feeling of “you are really smart like me” or “secretly regret”, which will affect my judgment on the next trip.

This is just as supply chains are becoming digitally intelligent, with transparent data that companies can use to make decisions. This process, if manual, may make mistakes, need to audit, need managers according to management experience, business logic to judge. So the key here is that the data can be presented truthfully on the same platform, with the same standards.

Against the world class, to achieve the leading central enterprises

China MOBILE HAS formed a two-level professional service system with 1 procurement and sharing center, 5 regional logistics centers and more than 50 branches. The two-level procurement management mechanism of “horizontal focal point and vertical concentration” covers all units of the group, standardizes the professional procurement language of the whole group, and realizes “the same language of books, trains and lines”. Supply chain management (SCM) system covers all units of wanda group, achieved from requirements gathering, procurement implementation to warehousing logistics of the whole process control, and well versed with ERP, contracts, reimbursement system, with a yard “created from an investment project to the planning, purchasing, order, warehouse, GongJian, d, for, and each link of the reverse logistics. The big data platform in the system has so far constructed 42 scenarios, controlled more than 3,000 cases of product quality risks, intercepted 560 cases of encircling bidding and string bidding, and promoted the overall efficiency of the industrial chain by 30%.

What level is that? China Mobile was awarded as one of the first batch of national “supply chain innovation and application” demonstration enterprises, and “digitalized supply chain management” was selected as the “benchmark project” of State-owned key enterprise management by the State-owned Assets Supervision and Administration Commission of the State Council. For many years, China Mobile has achieved excellent results in the procurement management improvement benchmark of central enterprises.

In April 2022, State-owned Assets Supervision and Administration Commission (SASAC) held a meeting to promote the bidding of the world-class procurement transaction management system, and China Mobile made a speech as an outstanding enterprise, fully realizing the “leading central enterprises”. At the conference, Li Huidi, vice general manager of China Mobile, took the “five modernization” as the main line, from strengthening intensive management, insisting on standardized construction, forging professional ability, promoting collaborative innovation, and exploring the application of digital intelligence. Focusing on the optimization of total life-cycle cost, embedded clean risk prevention and control mechanism in procurement field, strengthening the security defense line of “industrial chain and supply chain”, online synergy of upstream and downstream whole process, and building the capability of digitalized system, this paper introduced the company’s procurement and supply chain management work in recent years. A systematic summary and experience sharing of the company’s achievements in the implementation of SASAC’s “to improve the world’s first-class management” were carried out.

Service business strategies to increase resilience to growth

Supply chain strategy is an important part of enterprise core strategy. Supply chain strategy directly undertakes the three indexes (cost, service and inventory) of the operation level of strategic objectives, which serves the enterprise strategy and is also the operation chassis supporting the implementation of strategic measures.

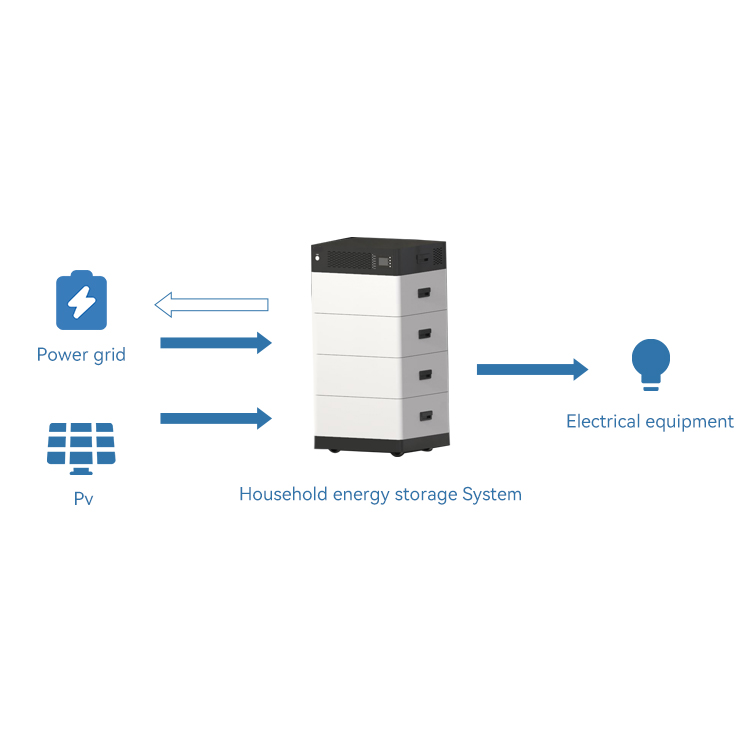

The world is undergoing profound changes unseen in a century, and the COVID-19 pandemic is a stress test for the growth resilience of companies in this new stage of development. On the one hand, security, risk and resilience are becoming more and more important in supply chain management; On the other hand, the application of new technologies such as big data, the Internet of Things, artificial intelligence and blockchain has accelerated significantly. The digital intelligence supply chain is a vast network linking the digital and physical worlds.

China MOBILE SETS UP THE development goal of “creating a world-class information service technology innovation company”, and puts forward the development main line of “promoting digitalization transformation and realizing high-quality development”. Supply chains have also been transformed to match this.

On September 9, 2022, China Mobile organized the launch meeting of Digital Wisdom supply chain management system construction project. The significance of digital wisdom supply chain, China Mobile deputy general manager Li Huidi pointed out at the meeting: digital wisdom supply chain management system construction is an important measure to resolutely implement the central decision and deployment; It is an important practice of the company’s new information service system of “connection + computing power + capability”. It is the foundation bearer for “world class supply chain”.

The construction goal of digital wisdom supply chain management system is also very clear: keep in mind the “overall situation optimal” goal, from the overall interests of the company, overall coordination of their own development and common development of the relationship; Keep in mind the goal of “value enhancement”, further promote efficient operation, support agile and flexible supply, and enhance the resilience of supply chain; Keep in mind the goal of “service production” to better serve the production line, partners and the overall production operation of the supply chain.

Specifically, China Mobile digital intelligent supply chain management system construction system is positioned as a centralized and unified digital intelligent production system of the whole group. It is necessary to improve the supply chain operation ability of the whole group, promote the digital intelligent transformation of the supply chain, and effectively support the integrated development of CHBN business. The project was launched in March 2022. The first phase of the project will reconstruct the five core capabilities, unify the standards, effectively improve the refinement level of the company’s supply chain management, strengthen the agility and flexibility of the supply chain, and build a win-win industrial chain ecology. Implementation work jointly organized by the Shared information technology center and sourcing center, the first phase of a pilot province company has zhejiang, hunan, Beijing, hebei, liaoning, anhui, shandong, we play “war built” together, focus and to carry out the renovation and alignment, the data cleansing, UAT testing and user training, and cut over online four key tasks.

Strengthen the resilience of supply chain, empower all links, help enterprises to more keenly capture environmental changes, more quickly respond to user needs, more precise organization construction and supply.

Focus on industrial transformation, digital transformation of the new paradigm

The 2022 Government Work Report clearly states that “we will encourage soes to focus on their main responsibilities and main industries, and improve their ability to support and drive industrial and supply chains”.

Single point of digital efficiency, has been unable to meet the needs of enterprise survival and development. The process of industrial digitalization is accelerating, and the digital economy has become an important engine driving long-term economic growth. In the new blue ocean of the digital economy, it is necessary to open up the whole supply chain. This is a new proposition of The Times.

In addition to completing its own digitalization upgrade and continuing to serve customers well, China Mobile digitalization supply Chain has also effectively opened its own supply chain capabilities and efficiently integrated supply chain elements in the society. Drive all links in the supply chain to transform together, become a new paradigm of industrial digitalization, and improve industrial efficiency at the macro level.

Through the application of electronic signature, electronic seal, auxiliary bid evaluation tools and other new technologies, China Mobile Green Procurement has carried out more than 45,000 online (paperless) projects, improved procurement efficiency by more than 10%, and reduced carbon emissions by 3.75 tons.

The nature of the pan-wide alliance of China Mobile’s new channel transformation is a S2b model (Supply chain platform to business), which is a supply chain platform serving small and medium-sized channels. Facing customer demand, drive the industrial chain “on the cloud with the number of intelligence”, empower the digitalization of small and medium-sized channels, carry out smart marketing and smart operation. It is a bit like an industrial platform. It builds system and data capabilities that are difficult for small and medium-sized channels to operate, integrates industrial chain services, improves operational efficiency, and better matches users’ demands for a better digital life.

If further extended, as an important hub of finance and the real economy, the data precipitated by the supply chain will connect tens of millions of small, medium and micro enterprises upstream and downstream of the industrial chain through supply chain finance, which will play an important supporting role in “ensuring access, stabilizing the chain and rescuing” for the real economy. According to public data, at present, it has provided financing support of a total of 20 billion yuan for more than 180 partners.

It is also the key responsibility of central enterprises to strengthen the security defense of industrial and supply chains. Aiming at key areas such as 5G, transmission, IT and basic software, China Mobile combs the technology card map and drives the industrial chain to tackle core technologies through investment-driven, procurement strategy guidance and diversified supply. On the basis of safety and control of the whole device, it further extended to key components, introduced domestic cpus from Haiguang, Kunpeng, Feiteng, etc., to continuously expand the autonomous and controllable proportion and improve the ultimate survivability.

“From industry to industry” is a good way to promote the intellectualization of supply chain.